DC12V LED Circuit Board With Battery Rechargeable LED PCB Assembly

Project Flow and Request

1. ODM Project Flow:

1).Customer requirements

2).Confirm requirements

3).Project determination

4).Start development

5).Confirm the sample

6).Mass production

Quotation Files Request For OEM Project

In order to provide you with the most efficient and accurate quote on manufacturing the requested unit, we ask that you provide us with the following information:

1.Gerber file,PCB file,Eagle file or CAD file are all acceptable

2.A detailed bill of materials (BOM)

3.Clear pictures of PCB or PCBA sample for us

4.Quantity and delivery required

5.Test method for PCBA to guarantee 100% good quality products.

6.Schematics file for PCB design if need to do function test.

7.A sample if available for better sourcing

8.CAD files for enclosure manufacturing if required

9.A complete wiring and assembly drawing showing any special assembly instructions if required.

PCB Assembly Process

Technical Requirement | Professional Surface-mounting and Through-hole soldering Technology |

Various sizes like 1206,0805,0603 components SMT technology | |

ICT(In Circuit Test),FCT(Functional Circuit Test) technology | |

PCB Assembly With UL,CE,FCC,Rohs Approval | |

Nitrogen gas reflow soldering technology for SMT | |

High Standard SMT&Solder Assembly Line | |

High density interconnected board placement technology capacity | |

Quote&Production Requirement | Gerber File or PCB File for Bare PCB Board Fabricatio |

Bom(Bill of Material) for Assembly,PNP(Pick and Place file) and Components Position also needed in assembly | |

To reduce the quote time, please provide us the full part number for each components,Quantity per board also the quantity for orders. | |

Testing Guide&Function Testing method to ensure the quality to reach nearly 0% scrap rate | |

OEM/ODM/EMS Services | PCBA, PCB assembly: SMT & PTH & BGA |

PCBA and enclosure design | |

Components sourcing and purchasing | |

Quick prototyping | |

Plastic injection molding | |

Metal sheet stamping | |

Final assembly | |

Test: AOI, In-Circuit Test (ICT), Functional Test (FCT) | |

Custom clearance for material importing and product exporting | |

Other PCB Assembly Equipments | SMT Machine: SIEMENS SIPLACE D1/D2 / SIEMENS SIPLACE S20/F4 |

Reflow Oven: FolunGwin FL-RX860 | |

Wave Soldering Machine: FolunGwin ADS300 | |

Automated Optical Inspection (AOI): Aleader ALD-H-350B,X-RAY Testing Service | |

Fully Automatic SMT Stencil Printer: FolunGwin Win-5 |

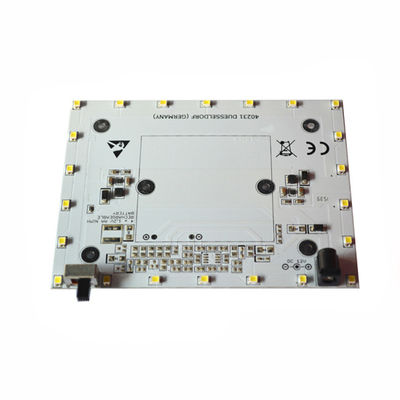

PCBA Picture

![]()