![]()

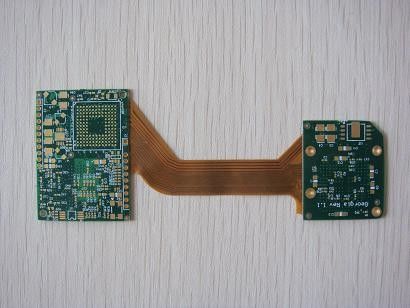

We are a Manufacturer & Supplier Specializing in Double Side PCB, Multi-Layer PCB, PTFE PCB, Ceramic PCB, Rogers PCB, Aluminium PCB, Flexible PCB with more than 10 years. Meanwhile, we provide PCBA ( Assembly) and ODM, OEM service. We are specializes in a full SMT and through hole PCBA assembly, obtaining components, building prototype quantities, and testing.

Our Production Capability for PCB

| Number of Layer | 1 - 20 Layer |

| Maximum Processing Area | 680 × 1000MM |

| Min Board Thickness | 2 Layer - 0.3MM ( 12 mil ) |

| 4 Layer - 0.4MM ( 16 mil ) | |

| 6 Layer - 0.8MM ( 32 mil ) | |

| 8 Layer - 1.0MM ( 40 mil) | |

| 10 Layer - 1.1MM ( 44 mil ) | |

| 12 Layer - 1.3MM ( 52 mil ) | |

| 14 Layer - 1.5MM ( 59 mil ) | |

| 16 Layer - 1.6MM ( 63 mil ) | |

| 18 Layer - 1.8MM ( 71 mil ) | |

| Finished Board Thickness Tolerance | Thickness ≤ 1.0MM, Tolerance: ± 0.1MM |

| 1.0MM ≤ Thickness ≤ 6.5MM, Tolerance ± 10% | |

| Twisting and Bending | ≤ 0.75%, Min: 0.5% |

| Range of TG | 130 - 215 ℃ |

| Impedance Tolerance | ± 10%, Min: ± 5% |

| Hi-Pot Test | Max: 4000V/10MA/60S |

| Surface Treatment | HASL, With Lead, HASL Free Lead |

| Flash Gold, Immersion Gold | |

| Immersion Silver, Immersion Tin | |

| Gold Finger, OSP |

Our PCBA Capability

SMT, PTH, mixed technology

SMT: 2,000,000 solder joints per day

DIP: 300,000 joints per day

Ultra fine pitch, QFP, BGA, μBGA, CBGA

Advanced SMT assembly

Automated insertion of PTH (axial, radial, dip)

Cleanable, aqueous and lead-free processing

RF manufacturing expertise

Peripheral process capabilities

Pressfit back planes & mid planes

Device programming

Automated conformal coating

For E-Test

Universal Tester

Flying Probe Open/Short Tester

High power Microscope

Solder ability Testing Kit

Peel Strength tester

High Volt Open & Short tester

Cross Section Molding Kit With Polisher

| If you need PCB assembly service as well, could you give us following information? | |

| 1. | Gerber file of the bare PCB board |

| 2. | BOM(Bill of material) for assembly |

| To short the Lead time, please kindly advise us if there is any acceptable components substitution. | |

| 3. | Testing Guide & Test Fixtures, if necessary |

| 4. | Programming files & Programming tool, is necessary |

| 5. | Schematic, if necessary |

![]()

![]()

![]()

![]()

![]()