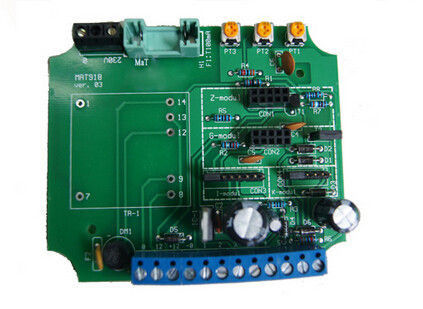

Auto Insertion electronic pcb assembly for GPS with AOI testing

1. Fast PCB Fabrication for Samples and Mass Production

2. Electronic Components Sourcing Services

3. PCBA Assembly Services:SMT,DIP,BGA...

4. Function Test

5. Stencil,Cable and Enclosure Assembly

6. Reverse engineering service

7. Standard Packing and On time Delivery

Engineering Support

PCB file will be checked by our PCB engineering team before production and PCBA boards will be test according to our engineering testing guide before shipment.

Customers Service

Every feedback to our service department will be dealt with in time.

Customers Solutions

Provide reasonable suggestion with the pcb files design and bom list choice to Enhance the competitiveness of product in the markets.

PCB Assembly with Full Tracking for Shipment:

Systematic order process, could check the production status of the entire purchase order

Main PCB Assembly Products Application

1. Household Appliances

2. Medical Products

3. Automotive Products

4. Industrial Products

5. Communication Products(AVL/GPS/GSM Devices)

6. Consumer Electronics

PCB Manufacturing Lead Time.

| Layer/Days | Sample(Normal) | Sample(Fast) | Mass Production |

| Single/Double | 2-3days | 24hours | 5-7days |

| Four Layer | 7-10days | 3days | 7-10days |

| Six Layer | 7-10days | 5days | 13-15days |

| Eight Layer | 15-20days | 7days | 15-20days |

Reverse Engineering of Electronic PCB Assembly Manufacturing Products

We has developed capabilities of generating the necessary manufacturing documentation from finished

products. Services include.

1. Artwork and PCB Scanning

2. Schematics and Gerber File Generation

2. Bill of Material and Parts List Generation

PCB Assembly Capabilities

| Turnkey PCBA | PCB+components sourcing+assembly+package |

| Assembly details | SMT and Thru-hole, ISO lines |

| Lead Time | Prototype: 15 work days. Mass order: 20~25 work days |

| Testing on products | Flying Probe Test, X-ray Inspection, AOI Test, functional test |

| Quantity | Min quantity: 1pcs. Prototype, small order, mass order, all OK |

| Files we need | PCB: Gerber files(CAM, PCB, PCBDOC) |

| Components: Bill of Materials(BOM list) | |

| Assembly: Pick-N-Place file | |

| PCB panel Size | Min size: 0.25*0.25 inches(6*6mm) |

| Max size: 20*20 inches(500*500mm) | |

| PCB Solder Type | Water Soluble Solder Paste, RoHS lead free |

| Components details | Passive Down to 0201 size |

| BGA and VFBGA | |

| Leadless Chip Carriers/CSP | |

| Double-sided SMT Assembly | |

| Fine Pitch to 0.8mils | |

| BGA Repair and Reball | |

| Part Removal and Replacement | |

| Component package | Cut Tape,Tube,Reels,Loose Parts |

| PCB assembly process |

Drilling-----Exposure-----Plating-----Etaching & Stripping-----Punching-----Electrical Testing-----SMT-----Wave Soldering-----Assembling-----ICT-----Function Testing-----Temperature & Humidity Testing |

The Most Professional OEM R D and Electronics PCB Assembly Contract Manufacturing Supplier In China.

1. PCB Assembly with Fast Delivery:

2. PCB 12hours and PCBA 3-5days for prototypes.

3. Provide the whole industry chain service,

4. From the pcb board, components purchase to pcb assembly,function testing and casing assembly.

Files Requested For PCB Assembly Quotation

In order to provide you with the most efficient and accurate quote on manufacturing the requested unit, we

ask that you provide us with the following information:

Gerber file,PCB file,Eagle file or CAD file are all acceptable

1. A detailed bill of materials (BOM)

2. Clear pictures of PCB or PCBA sample for us

3. Quantity and delivery required

4. Test method for PCBA to guarantee 100% good quality products.

5. Schematics file for PCB design if need to do function test.

6. A sample if available for better sourcing

7. CAD files for enclosure manufacturing if required

8. A complete wiring and assembly drawing showing any special assembly instructions if required