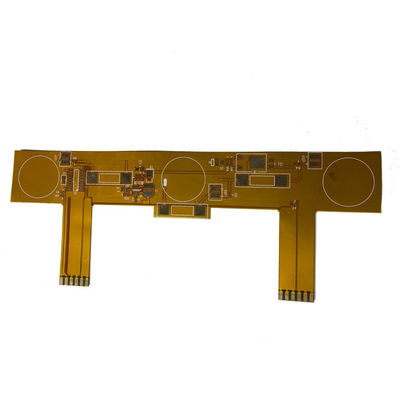

Reliable 2 layer flexible PCB Board Laser Cut Sample Board Polyimide PCB

This is a type of flexible printed circuit for the application of antenna. It’s a 2 layer FPC at 0.2mm thick. The base laminate is from ITEQ, It’s fabricated per IPC 6012 Class 2 using supplied Gerber data. FR-4 as stiffner is applied at the bottom side.

Flexible circuits are also used extensively in other applications and industries including:

Communications

Consumer Electronics

Automotive

Medical

Industrial

Aerospace

Military

Transportation

Parameter and data sheet

|

Max. Size of Flexible PCB |

600*400mm |

|

Max. Number of Layers |

8 |

|

Board Type |

Flexible PCB |

|

Board Thickness |

0.15mm |

|

Board Material |

PET 25µm |

|

Board Material Supplier |

Shengyi |

|

Tg Value of Board Material |

60℃ |

|

|

|

|

PTH Cu thickness |

≥20 µm |

|

Inner Iayer Cu thicknes |

N/A |

|

Surface Cu thickness |

35 µm |

|

|

|

|

Coverlay Colour |

Yellow Top / White Bottom |

|

Number of Coverlay |

2 |

|

Thickness of Coverlay |

25 µm |

|

Stiffener Material |

Polyimide |

|

Stiffener Thickness |

0.2mm |

|

|

|

|

Type of Silkscreen Ink |

IJR-4000 MW300 |

|

Supplier of Silkscreen |

TAIYO |

|

Color of Silkscreen |

Black |

|

Number of Silkscreen |

1 |

|

|

|

|

Peeling test of Coverlay |

No peelable |

|

Legend Adhesion |

3M 90℃ No peeling after Min. 3 times test |

|

|

|

|

Surface Finish |

Immersion Gold |

|

Thickness of Nickle/Gold |

Au: 0.03µm(Min.); Ni 2-4µm |

|

RoHS Required |

Yes |

|

Famability |

94-V0 |

|

|

|

|

Thermal Shock Test |

Pass, -25℃±125℃, 1000 cycles. |

|

Thermal Stress |

Pass, 300±5℃,10 seconds, 3 cycles. No delamination, no blistering. |

|

Function |

100% Pass electrical test |

|

Workmanship |

Compliance with IPC-A-600H & IPC-6013C Class 2 |

Flexible PCB / FPCB Applications

FPCBs are used widely in everyday technology and electronics in addition to high-end, complex completed components. Two of the most prominent examples of flexible circuit usage is in modern portable electronics, devices, hard disk drives and desktop printers.

FPCB Photo

![]()

![]()