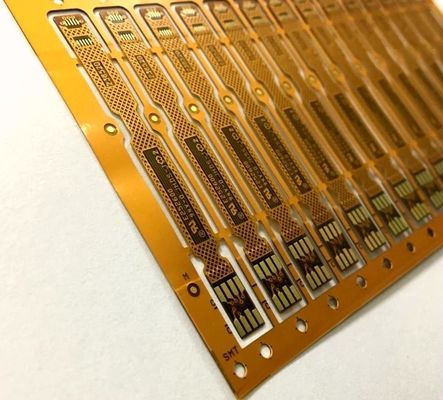

PI Material FPC double sides 2.0oz copper thickness flexible pcb

Number of layers: 2 layers

Material: FPC

Board thickness: 1.6mm

Surface plating: ENIG

Min Trace: 3mil

Silkscreen:White

With 14+ years of experience exporting PCBs overseas, We understands the needs of your business and welcomes the opportunity to serve you.

Shinelink Company philosophy is simple- Deliver quality printed circuit boards on time.

We are ISO 9001:2008 certified.

Our dedication to building a quality product is the centerpiece of our business policy.

We are committed to fulfilling our customers' on-going quality requirements through continuous improvements to all of our internal processes. Our quality management system ensures the highest operating standards at all levels.

|

Item |

Mass production |

Small batch production |

||

|

Number of layers |

UP TO 18L |

UP TO L |

||

|

Laminate type |

FR-4, halogen free, high TG(Shengyi, KB), Cem-3, PTFE, aluminum based, PTEE, Rogers or more. |

FR-4, Halogen free, High TG(Shengyi, KB), Cem-3, PTFE, Aluminum based, PTEE, Rogers or more. |

||

|

Maximum board size |

610mm*1100mm |

610mm*1100mm |

||

|

Board thickness |

0.1mm-7.00mm |

<0.1mm and >7.00mm |

||

|

Minimum line width/space |

3.5mil(0.0875mm) |

3mil(0.075mm) |

||

|

Minimum line gap |

+/-15% |

+/-10% |

||

|

Outer layer copper thickness |

35um-175um |

35um-210um |

||

|

Inner layer copper thickness |

12um-175um |

12um-210um |

||

|

Drilling hole size(Mechanical) |

0.15mm-6.5mm |

0.15mm-6.5mm |

||

|

Finished hole size (Mechanical) |

0.15mm-6.0mm |

0.15mm-6.0mm |

||

|

Board thickness hole size ratio |

14:1 |

16:1 |

||

|

Board thickness tolerance(t=0.8mm) |

±8% |

±5% |

||

|

Board thickness tolerance(t<0.8mm) |

±10% |

±8% |

||

|

Min. grid line width |

4mil(12, 18, 35um), 6mil(70um) |

4mil(12, 18, 35um), 6mil(70um) |

||

|

Min. grid spacing |

6mil(12, 18, 35um), 8mil(70um) |

6mil(12, 18, 35um), 8mil(70um) |

||

|

Hole size tolerance(Mechanical) |

0.05-0.075mm |

0.05mm |

||

|

Hole position tolerance(Mechanical) |

0.005mm |

0.005mm |

||

|

Solder mask color |

Green, Blue, Black, White, Yellow, Red, Grey etc. |

Green, Blue, Black, White, Yellow, Red, Grey etc. |

||

|

Impedance control tolerance |

+/-10% |

+/-8% |

||

|

Min. distance between drilling to conductor(non-blind buried orifice) |

8mil(8L), 9mil(10L), 10mil(14L), 12mil(26L) |

6mil(8L), 7mil(10L), 8mil(14L), 12mil(26L) |

||

|

Min. Character width and height(35um base copper) |

Line width: 5mil |

Line width: 5mil; height: 27mil |

||

|

Max. test voltage |

500V |

500V |

||

|

Max. test current |

200mA |

200mA |

||

|

|

Flash Gold |

0.025-0.075um |

0.025-0.5um |

|

|

Immersion Gold |

0.05-0.1um |

0.1-0.2um |

||

|

Sn/Pb HASL |

1-70um |

1-70um |

||

|

Lead-free HASL |

1-70um |

1-70um |

||

|

Immersion Silver |

0.08-0.3um |

0.08-0.3um |

||

|

OSP |

0.2-0.4um |

0.2-0.4um |

||

|

Gold Finger |

0.375um |

>=1.75um |

||

|

Hard Gold Plating |

0.375um |

>=1.75um |

||

|

Immersion Sin |

0.8um |

|

||

|

V-Cut rest thickness tolerance |

±0.1mm |

±0.1mm |

||

|

|

Chamfer |

The angle type of the chamfer |

30,45,60 |

|

|

Plug via hole |

Max.size can be plugged |

0.6mm |

||

|

Largest NPTH hole size |

6.5mm |

>6.5mm |

||

|

Largest PTH hole size |

6.5mm |

>6.5mm |

||

|

Min. solder spacer ring |

0.05mm |

0.05mm |

||

|

Min. solder bridge width |

0.1mm |

0.1mm |

||

|

Drilling diameter |

0.15mm-0.6mm |

0.15mm-0.6mm |

||

|

Min. pad diameter with hole |

14mil( 0.15mm drilling) |

12mil( 0.1mm laser) |

||

|

Min. BGA pad diameter |

10mil |

8mil |

||

|

Chemical ENIG gold thickness |

0.025-0.1um(1-4U) |

0.025-0.1um |

||

|

Chemical ENIG nickel thickness |

3-5um(120-200U) |

3-5um |

||

|

Min. resistance test |

Ω |

5 |

||

FPCB Picture

![]()